| HOME |

| RESEARCH |

| PEOPLE |

| TEACHING |

| PATENTS AND PUBLICATIONS |

| FACILITIES |

| EVENTS & AWARDS |

| COLLABORATORS |

| CONTACT US |

![]()

NOVEL TECHNIQUES

FOR SENSING APPLICATIONS BINDERLESS

CONDUCTIVE INKS

FOR STRUCTURAL HEALTH MONITORING

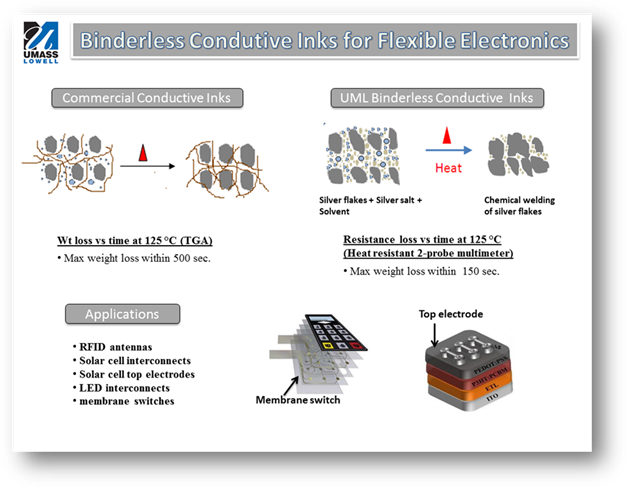

We are developing novel silver conductive inks that do not contain any polymeric binders in the formulation unlike commercially available silver conductive inks. Polymeric binders in inks serve as a transport agent and also hold the silver flakes together. Our formulation contains a silver organometallic salt which decomposes at temperatures of 120 oC to give reactive silver which chemically welds the silver flakes together. We also employ a unique solvent system which acts as transport system for the inks and keeps the flakes uniformly dispersed in the solution. The basic aims of our study is: (1) To make high conductive inks that can reach conductivity of at least one magnitude less than that of silver ( 6.3 × 107 ) at low sintering temperatures of below 120 oC. (2) To ensure that the ink maintains a stable viscosity during printing process in roll to roll coating/printing process. The inks can be printed on flexible substrates such as polyester films to form pin-hole free conductive patterns. Applications of our inks can range from interconnects for solar cells, LEDs and flexible RFID antennas

|