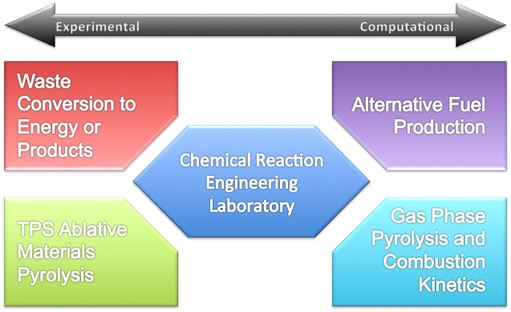

Chemical Reaction Engineering Laboratory (CREL)

The Chemical Reaction Engineering Laboratory (CREL) at the University of Massachusetts Lowell focuses on utlizing both experimental and theoretical techniques to investigate complex reaction systems in energy and environmental problems. Key research expertise of our laboratory includes high temperature pyrolysis and oxidation experiments and detailed kinetic modeling.

Current research directions include:

Waste conversion to energy and/or high-value products

Waste recycling has been one of the most critical environmental issues. Thermochemical conversion of discarded materials into energy or high-value products provides the best long-term solutions. The most common waste to energy approach is to convert solid wastes into fuels. This route, while proven feasible, has very high energy requirements with only moderate value end products. Another route is to utilize the carbon atoms in the waste to produce high value carbon nanomaterials, such as carbon nanotubes, fullerenes, and graphene. This is a much more economical path, but state-of-the-art scientific understanding to break through the technical barriers remains very limited. Our group is focusing on discovering the detailed reaction kinetics of the system to enable future optimization and development of waste conversion to both energy and high-value products.

Production of hydrocarbon fuels from alternative sources

Concerns associated with increasing oil prices coupled with environmental and national security issues have triggered a search for new sources of liquid fuels to supplement, and if possible, to replace current petroleum-derived fuels. Producing hydrocarbon fuels from non-traditional (i.e., non-petroleum) sources presents the most viable option, since they can be directly implemented into the current infrastructure and use in the internal combustion engine. Our group is actively researching the production of hydrocarbon fuels from alternative sources and pathways, such as biomass, waste plastics, and direct conversion from carbon dioxide and water.

Pyrolysis chemistry of thermal protection system ablative materials

Thermal Protection Systems (TPS) ablative materials are used to protect space vehicles during re-etry when the ablation process dramatically heats up the vehicle surfaces. One of the critical steps in ablative material development is to provide state-of-the-art material-response models to ensure optimal heat-shield design. In-depth knowledge of the pyrolysis kinetics of the virgin TPS materials exposed to a high-temperature, low-pressure environment is essential for an accurate model. Our group is using novel custom-made reactor setups to investigate the reaction kinetics and species production from the pyrolysis of TPS materials.

Detailed reaction kinetics of gas phase pyrolysis and combustion chemistry

High temperature pyrolysis and combustion chemistry often involves a large number of intermediate species and reactions. Tracking this level of details while obtaining fundamental understanding is a formidable task. Our group is developing experimental and theoretical techniques to unravel detailed kinetics of high temperature pyrolysis and combustion chemistry and tools to enable easy understanding of complex interactions in the systems.