|

Chemistry 2 - Course

#84.122

SECTIONS 202, 223, and 227

|

|

NEAT SCIENCE

http://nanotechwire.com/

3/2/2011 5:46:15 PM

Stronger Than Steel, Novel Metals Are Moldable as Plastic

Imagine a material that's stronger than steel, but just as

versatile as plastic, able to take on a seemingly endless variety of forms. For

decades, materials scientists have been trying to come up with just such an

ideal substance, one that could be molded into complex shapes with the same ease

and low expense as plastic but without sacrificing the strength and durability

of metal.

Now a team led by Jan Schroers, a materials scientist at

Yale University, has shown that some recently developed bulk metallic glasses (BMGs)-metal

alloys that have randomly arranged atoms as opposed to the orderly, crystalline

structure found in ordinary metals-can be blow molded like plastics into complex

shapes that can't be achieved using regular metal, yet without sacrificing the

strength or durability that metal affords. Their findings are described online

in the current issue of the journal Materials Today.

"These alloys look like ordinary metal but can be blow

molded just as cheaply and as easily as plastic," Schroers said. So far the team

has created a number of complex shapes-including seamless metallic bottles,

watch cases, miniature resonators and biomedical implants-that can be molded in

less than a minute and are twice as strong as typical steel.

The materials cost about the same as high-end steel,

Schroers said, but can be processed as cheaply as plastic. The alloys are made

up of different metals, including zirconium, nickel, titanium and copper.

The team blow molded the alloys at low temperatures and

low pressures, where the bulk metallic glass softens dramatically and flows as

easily as plastic but without crystallizing like regular metal. It's the low

temperatures and low pressures that allowed the team to shape the BMGs with

unprecedented ease, versatility and precision, Schroers said. In order to

carefully control and maintain the ideal temperature for blow molding, the team

shaped the BMGs in a vacuum or in fluid.

"The trick is to avoid friction typically present in

other forming techniques," Schroers said. "Blow molding completely eliminates

friction, allowing us to create any number of complicated shapes, down to the

nanoscale."

Schroers and his team are already using their new

processing technique to fabricate miniature resonators for

microelectromechanical systems (MEMS)-tiny mechanical devices powered by

electricity-as well as gyroscopes and other resonator applications.

In addition, by blow molding the BMGs, the team was able

to combine three separate steps in traditional metal processing (shaping,

joining and finishing) into one, allowing them to carry out previously

cumbersome, time- and energy-intensive processing in less than a minute.

"This could enable a whole new paradigm for shaping

metals," Schroers said. "The superior properties of BMGs relative to plastics

and typical metals, combined with the ease, economy and precision of blow

molding, have the potential to impact society just as much as the development of

synthetic plastics and their associated processing methods have in the last

century."

Other authors of the paper include Thomas M. Hodges and

Golden Kumar (Yale University); Hari Raman and A.J. Barnes (SuperformUSA); and

Quoc Pham and Theodore A. Waniuk (Liquidmetal Technologies).

http://nanotechwire.com/

3/2/2011 5:50:43 PM

Professor uses nanotechnology to prolong machine and engine life

Guojun Liu has discovered a way to use nanotechnology to

reduce friction in automobile engines and machines.

“The technology should be useful in a wide range of

machineries other than automobile engines,” says Dr. Liu, a professor in the

Department of Chemistry and an expert in polymer synthesis. “If implemented

industrially, this nanotechnology should help prolong machine life and improve

energy efficiency.”

Dr Liu’s team prepared miniscule polymer particles that

were only tens of nanometers in size. These particles were then dispersed in

automobile engine base oils. When tested under metal surface contact conditions

that simulated conditions found in automobile engines, these tiny particles were

discovered to have an unprecedented friction reduction capability.

Even at a low concentration, the nanoparticles performed

much better than the friction additive that is currently used by many

industries. They were able to reduce friction by 55 per cent more than the

currently achievable rate.

Dr. Liu’s discovery has earned the Society of

Tribologists and Lubrication Engineers’ Captain Alfred E. Hunt Memorial Award.

This prestigious award is given annually to the STLE member who authors the best

paper dealing with the field of lubrication or an allied field.

This is the first research that Dr. Liu has done in the

field of friction reduction and lubrication.

Dec. 20, 2010

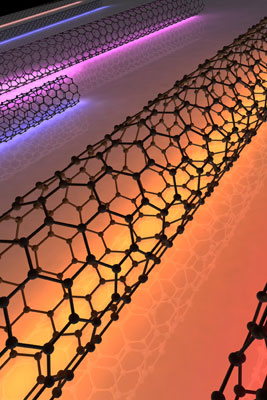

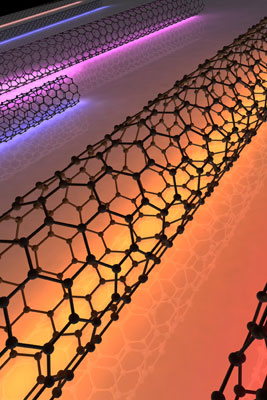

Carbon nanotubes could be ideal optical antennae

|

Shivank

Garg Shivank

Garg |

|

An artistic

rendering of carbon nanotubes scattering light. |

By

Anne Ju

Just as walkie-talkies transmit and receive radio waves, carbon

nanotubes can transmit and receive light at the nanoscale, Cornell researchers

have discovered.

Carbon nanotubes, cylindrical rolled-up sheets of carbon atoms,

might one day make ideal optical scattering wires -- tiny, mostly invisible

antennae with the ability to control, absorb and emit certain colors of light at

the nanoscale, according to research led by Jiwoong Park, Cornell assistant

professor of chemistry and chemical biology. The study, which includes co-author

Garnet Chan, also in chemistry, is published online Dec. 19 in the journal

Nature Nanotechnology. The paper's first author is Daniel Y. Joh, a former

student in Park's lab.

The researchers used the Rayleigh scattering of light -- the same

phenomenon that creates the blue sky -- from carbon nanotubes grown in the lab.

They found that while the propagation of light scattering is mostly classical

and macroscopic, the color and intensity of the scattered radiation is

determined by intrinsic quantum properties. In other words, the nanotubes'

simple carbon-carbon bonded molecular structure determined how they scattered

light, independent of their shape, which differs from the properties of today's

metallic nanoscale optical structures.

"Even if you chop it down to a small scale, nothing will change,

because the scattering is fundamentally molecular," Park explained.

They found that the nanotubes' light transmission behaved as a

scaled-down version of radio-frequency antennae found in walkie-talkies, except

that they interact with light instead of radio waves. The principles that govern

the interactions between light and the carbon nanotube are the same as between

the radio antenna and the radio signal, they found.

To

perform their experiments, the researchers used a methodology developed in their

lab that completely eliminates the problematic background signal, by coating the

surface of a substrate with a refractive index-matching medium to make the

substrate "disappear" optically, not physically. This technique, which allowed

them to see the different light spectra produced by the nanotubes, is detailed

in another study published in Nano Letters.

The technique also allows quick, easy characterization of a large

number of nanotubes, which could lead to ways of growing more uniform batches of

nanotubes.

The paper's principal authors are former student Daniel Y. Joh;

graduate student Lihong Herman; and Jesse Kinder, a postdoctoral research

associate in Chan's lab. Park is a member of the Kavli Institute at Cornell for

Nanoscale Science. Both the Nature Nanotechnology and Nano Letters work were

supported by the Air Force Office of Scientific Research and the National

Science Foundation through the Center for Nanoscale Systems, Cornell Center for

Materials Research, Center for Molecular Interfacing and an NSF CAREER grant.

http://www.news.cornell.edu/stories/Dec10/ParkNanotubes.html

Platinum-coated nanoparticles could power fuel cell cars

Fuel cells may power the cars of the future, but it's not enough

to just make them work -- they have to be affordable. Cornell researchers have

developed a novel way to synthesize a fuel cell electrocatalytic material

without breaking the bank.

The research, published online Nov. 24 in the Journal of the

American Chemical Society, describes a simple method for making nanoparticles

that drive the electrocatalytic reactions inside room-temperature fuel cells.

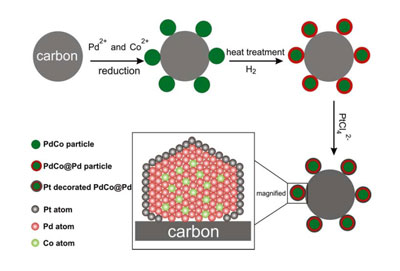

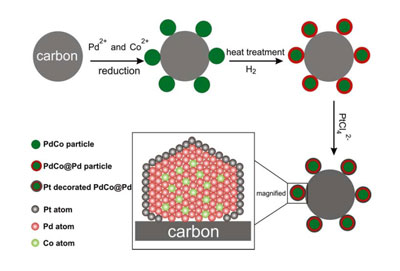

An illustration of the synthesis procedure of the core-shell

nanoparticles and subsequent deposition of platinum.

Fuel cells convert chemical energy directly into electrical

energy. They consist of an anode, which oxidizes the fuel (such as hydrogen),

and a cathode, which reduces oxygen to water. A polymer membrane separates the

electrodes. Fuel cell-powered cars in production today use pure platinum to

catalyze the oxygen reduction reaction in the cathode side. While platinum is

the most efficient catalyst available today for the oxygen reduction reaction,

its activity is limited, and it is rare and expensive.

The Cornell researchers' nanoparticles offer an alternative to

pure platinum at a fraction of the cost. They are made of a palladium and cobalt

core and coated with a one-atom-thick layer of platinum. Palladium, though not

as good a catalyst, has similar properties as platinum (it is in the same group

on the Periodic Table of Elements; it has the same crystal structure; and it is

similar in atomic size), but it costs one-third less and is 50 times more

abundant on Earth.

Researchers led by Héctor D. Abruña, the E.M. Chamot Profesor of

Chemistry and Chemical Biology, made the nanoparticles on a carbon substrate and

made the palladium-cobalt core self-assemble -- cutting down on manufacturing

costs. First author Deli Wang, a postdoctoral associate in Abruña's lab,

designed the experiments and synthesized the nanoparticles.

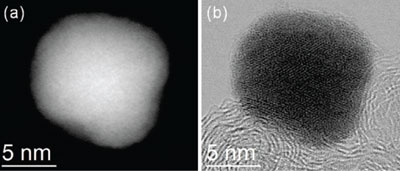

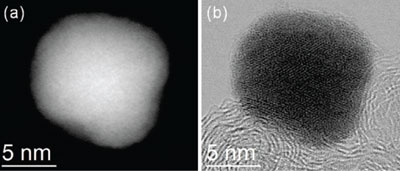

Atomic resolution images of the palladium-cobalt nanoparticle,

before platinum deposition.

David Muller, professor of applied and engineering physics and

co-director of the Kavli Institute at Cornell for Nanoscale Science, led the

efforts geared at imaging the particles down to atomic resolution to demonstrate

their chemical composition and distribution, and to prove the efficacy of the

catalytic conversions.

"The crystal structure of the substrate, composition and spatial

distribution of the nanoparticles play important roles in determining how well

the platinum performs," said Huolin Xin, a graduate student in Muller's lab.

The work was supported by the Energy Materials Center at Cornell,

a Department of Energy-supported Energy Frontiers Research Center. Researchers

also used equipment at the Cornell Center for Materials Research.

http://nanotechwire.com/news.asp?nid=11242

12/22/2010 4:08:51 PM

Ever-sharp urchin teeth may yield tools that never need honing

To survive in a tumultuous environment, sea urchins literally eat

through stone, using their teeth to carve out nooks where the spiny creatures

hide from predators and protect themselves from the crashing surf on the rocky

shores and tide pools where they live.

The rock-boring behavior is astonishing, scientists agree, but

what is truly remarkable is that, despite constant grinding and scraping on

stone, urchin teeth never, ever get dull. The secret of their ever-sharp

qualities has puzzled scientists for decades, but now a new report by scientists

from the University of Wisconsin-Madison and their colleagues has peeled back

the toothy mystery.

Writing today (Dec. 22, 2010) in the journal Advanced Functional

Materials, a team led by UW-Madison professor of physics Pupa Gilbert describes

the self-sharpening mechanism used by the California purple sea urchin to keep a

razor-sharp edge on its choppers.

The urchin's self-sharpening trick, notes Gilbert, is something

that could be mimicked by humans to make tools that never need honing.

"The sea urchin tooth is complicated in its design. It is one of

the very few structures in nature that self-sharpen," says Gilbert, explaining

that the sea urchin tooth, which is always growing, is a biomineral mosaic

composed of calcite crystals with two forms — plates and fibers — arranged

crosswise and cemented together with super-hard calcite nanocement. Between the

crystals are layers of organic materials that are not as sturdy as the calcite

crystals.

"The organic layers are the weak links in the chain," Gilbert

explains. "There are breaking points at predetermined locations built into the

teeth. It is a concept similar to perforated paper in the sense that the

material breaks at these predetermined weak spots."

The crystalline nature of sea urchin dentition is, on the

surface, different from other crystals found in nature. It lacks the obvious

facets characteristic of familiar crystals, but at the very deepest levels the

properties of crystals are evident in the orderly arrangement of the atoms that

make up the biomineral mosaic teeth of the sea urchin.

To delve into the fundamental nature of the crystals that form

sea urchin teeth, Gilbert and her colleagues used a variety of techniques from

the materials scientist's toolbox. These include microscopy methods that depend

on X-rays to illuminate how nanocrystals are arranged in teeth to make the sea

urchins capable of grinding rock. Gilbert and her colleagues used these

techniques to deduce how the crystals are organized and melded into a tough and

durable biomineral.

Knowing the secret of the ever-sharp sea urchin tooth, says

Gilbert, could one day have practical applications for human toolmakers. "Now

that we know how it works, the knowledge could be used to develop methods to

fabricate tools that could actually sharpen themselves with use," notes Gilbert.

"The mechanism used by the urchin is the key. By shaping the object

appropriately and using the same strategy the urchin employs, a tool with a

self-sharpening edge could, in theory, be created."

The new research was supported by grants from the U.S. Department

of Energy and the National Science Foundation. In addition to Gilbert,

researchers from the University of California, Berkeley; Argonne National

Laboratory; the Weizmann Institute of Science; and the Lawrence Berkeley

National Laboratory contributed to the report.

http://www.news.wisc.edu/18804

12/9/2010 11:33:02 AM

Better batteries from the bottom up

Rice University researchers have moved a step closer to creating

robust, three-dimensional microbatteries that would charge faster and hold other

advantages over conventional lithium-ion batteries. They could power new

generations of remote sensors, display screens, smart cards, flexible

electronics and biomedical devices.

The batteries employ vertical arrays of nickel-tin nanowires

perfectly encased in PMMA, a widely used polymer best known as Plexiglas. The

Rice laboratory of Pulickel Ajayan found a way to reliably coat single nanowires

with a smooth layer of a PMMA-based gel electrolyte that insulates the wires

from the counter electrode while allowing ions to pass through.

The work was reported this week in the online edition of the

journal Nano Letters.

"In a battery, you have two electrodes separated by a thick

barrier," said Ajayan, professor in mechanical engineering and materials science

and of chemistry. "The challenge is to bring everything into close proximity so

this electrochemistry becomes much more efficient."

Ajayan and his team feel they've done that

by growing forests of coated nanowires -- millions of them on a fingernail-sized

chip -- for scalable microdevices with greater surface area than conventional

thin-film batteries. "You can't simply scale the thickness of a thin-film

battery, because the lithium ion kinetics would become sluggish," Ajayan said.

"We wanted to figure out how the proposed 3-D designs of

batteries can be built from the nanoscale up," said Sanketh Gowda, a graduate

student in Ajayan's lab. "By increasing the height of the nanowires, we can

increase the amount of energy stored while keeping the lithium ion diffusion

distance constant."

The researchers, led by Gowda and postdoctoral researcher Arava

Leela Mohana Reddy, worked for more than a year to refine the process.

"To be fair, the 3-D concept has been around for a while," Reddy

said. "The breakthrough here is the ability to put a conformal coat of PMMA on a

nanowire over long distances. Even a small break in the coating would destroy

it." He said the same approach is being tested on nanowire systems with higher

capacities.

The process builds upon the lab's previous research to build

coaxial nanowire cables that was reported in Nano Letters last year. In the new

work, the researchers grew 10-micron-long nanowires via electrodeposition in the

pores of an anodized alumina template. They then widened the pores with a simple

chemical etching technique and drop-coated PMMA onto the array to give the

nanowires an even casing from top to bottom. A chemical wash removed the

template.

They have built one-centimeter square microbatteries that hold

more energy and that charge faster than planar batteries of the same electrode

length. "By going to 3-D, we're able to deliver more energy in the same

footprint," Gowda said.

They feel the PMMA coating will increase the number of times a

battery can be charged by stabilizing conditions between the nanowires and

liquid electrolyte, which tend to break down over time.

The team is also studying how cycling affects nanowires that,

like silicon electrodes, expand and contract as lithium ions come and go.

Electron microscope images of nanowires taken after many charge/discharge cycles

showed no breaks in the PMMA casing -- not even pinholes. This led the

researchers to believe the coating withstands the volume expansion in the

electrode, which could increase the batteries' lifespans.

Co-authors are Rice graduate student Xiaobo Zhan; former Rice

postdoctoral researcher Manikoth Shaijumon, now an assistant professor at the

Indian Institute of Science Education and Research, Thiruvananthapuram, India;

and former Rice research scientist Lijie Ci, now a senior research and

development manager at Samsung Cheil Industries.

The Hartley Family Foundation and Rice University funded the

research.

Read the abstract at http://pubs.acs.org/doi/abs/10.1021/nl102919m

nanotechwire.com 1/21/2011 5:09:06 PM

Butterfly wings behind anti-counterfeiting technology

Imagine a hole so small that air can’t go through it, or a

hole so small it can trap a single wavelength of light. Nanotech Security Corp.,

with the help of Simon Fraser University researchers, is using this type of nano-technology

– 1,500 times thinner than a human hair and first of its kind in the world – to

create unique anti-counterfeiting security features.

The technology is first being applied to banknotes but it

also has many more practical applications, such as authenticating legal

documents, retail merchandise, concert tickets, stock certificates, visas,

passports, and pharmaceuticals.

SFU applied sciences grad Clint Landrock started the

initial research into nanoholes under the guidance of SFU engineering science

professor Bozena Kaminska. When the pair pitched their idea to Doug Blakeway,

SFU Venture Connection’s entrepreneur in residence and also CEO and chairman of

Nanotech, he was immediately intrigued by the technology’s potential.

“I love nanotechnology but I really have not seen a

commercialization of it that can make you money in the near term,” said Blakeway.

“When this was initially presented to me by Bozena and Clint, I immediately saw

their vision and they were only after one application – creating

anti-counterfeiting features for banknotes. I felt this could be the first

commercial application of nanotechnology in the world. I kept thinking of

applications for it and how it could be used; the technologies and potential

astound me.”

Landrock and Kaminska both continue their work as part

of Nanotech’s scientific team. The company’s Nano-Optic Technology for Enhanced

Security (NOtES) product stems from an idea originating in the purest form of

nature – insects using colorful markings to identify themselves.

How this works is microscopic gratings composed of

nanostructures interact with light to produce the shimmering iridescence seen on

the Costa Rican morpho butterfly. The nanostructures act to reflect and refract

light waves to produce the morpho’s signature blue wings and absorb other

unwanted light.

The highly advanced wing structures are the result of

many millennia of evolution, and only recently have Nanotech's scientists

discovered how to reproduce these structures reliably. While others have talked

about the possibility of re-creating it, Nanotech has made this a reality.

The U.S. Treasury, which produces up to 11 billion

banknotes annually, is a potential customer for Nanotech’s product. The new U.S.

$100 bill, designed with state-of-the art security features, was supposed to be

introduced in February 2011 but it’s been delayed due to some manufacturing

issues.

Banknotes contain several security features – some that

you can plainly see and some that only machines can read – such as hologram

strips, security threads woven into the paper, watermarks, color-shifting inks,

raised type, and UV inks.

According to Blakeway, Nanotech’s product – which has

attracted the attention of treasuries internationally – is superior to holograms

and can’t be duplicated.

“Nobody has ever done this,” he said. “We have succeeded

while everybody is still trying to duplicate or imitate a butterfly’s wing

because it absorbs light and gives off the color. There’s no color pigment –

there’s nothing like a dye or anything else. It’s a hole that traps light and

releases color.

“You can’t copy or scan it in, you can’t inkjet it on

paper, you can’t do any of these things. It’s extremely sophisticated and

expensive to make the shims and dyes to produce, but very inexpensive to produce

it at the end. Anywhere you can think of where a hologram is being used today,

our technology can replace it. It’s more secure than a hologram. You can’t lift

it off – we can put it onto metal, plastic, or paper.”

SFU Venture Connections offers training and support

programs for SFU entrepreneurs. It links students, faculty and local

entrepreneurs with experienced advisors and funding opportunities.

The Secret of Bright Butterfly Wings: LED

Technology

By

Ker Than, LiveScience Staff Writer

posted: 17 November 2005 02:01 pm ET

Science was way behind nature in developing

LED light

technology, a new study finds.

The beautifully colored wings of African

swallowtail butterflies manipulate light using engineering

tricks similar to those found in digital displays. The

butterflies have black wings with

bright patches of green and blue, which they use to

communicate across long distances.

Microscopic scales covering the wings absorb ultraviolet

light and then re-emit it.

The re-emitted light interacts with

fluorescent pigments found on the butterflies’ wings to produce

the vibrant green-blue color.

Like LEDs

Researchers investigating how the scales work

found that they have many similarities to digital devices known

as light emitting diodes, also known as

LEDs, which are found in everything from computer and

television screens to traffic lights.

The first LEDs invented in the late 1960s

weren’t very bright. They produced a lot of light but most of it

tended to either become trapped inside the device or to spread

sideways and become diluted.

In the early 1990s, engineers came up with

ways to get around these problems. They outfitted LEDs with tiny

mirrors that could reflect and channel the light and made

microscopic holes in them to help the light escape.

Behind the

butterflies

While studying the wings of swallowtail

butterflies, researchers discovered that there were

a lot of similarities between the

scale coverings and LEDs.

The scales that cover the butterflies’ wings

contain tiny structures called “photonic crystals,” which act

very much like the microholes found in LEDs.

“[The scales] prevent the fluorescent light

from being trapped inside the scales and from being emitted

sideways,” said Pete Vukusic of Exeter

University, a researcher in the study.

The scales on the wing also have a

specialized mirror underneath them, which act very much like the

tiny mirrors found in LEDs.

The mirror reflects all the scattered

fluorescent light it receives upward, giving the butterflies

control over the direction in which in the light is emitted.

The

study was reported in the Nov. 18 issue of the journal

Science.

NANOTECHWIRE.COM

1/21/2011 5:06:58 PM

Nanotechnology Institute creates safe endoscopes

An interdisciplinary team of Drexel researchers have

created the first endoscope that can probe an individual cell without causing

harm - a discovery that could have wide-ranging scientific benefits, according

to project coordinator Yury Gogotsi.Gogotsi is

director of the A. J. Drexel Nanotechnology Institute as well as a materials

science and engineering professor.

The ability to inject single cells is described by

Gogotsi as "one of the pipe dreams existing for a very long time" in the field

of nanotechnology. He added that such a vision is popular in artists' renderings

for nanotechnology.

Gogotsi explained that one reason for this interest in a

single cell endoscope is because much of current cell experimentation destroys

tested cells. He said the fact that Drexel's endoscope can study parts of single

cells without affecting the cell itself "is very important for cell biology."

In addition, Gogotsi said being able to look at single

cells could greatly help researchers create new drugs.

The Drexel researchers made the endoscope by placing a

carbon nanotube, which is roughly a thousand times thinner than a human hair,

onto the tip of a glass pipette. The endoscope conducts electricity in order to

take electrochemical measurements in cells. Gogotsi said that because cells send

signals using ionic currents, "measuring these currents is very important."

The endoscope is also magnetic and fluorescent, allowing

scientists to move it around the cell and see it under a microscope.

Riju Singhal, a doctoral student in materials

engineering and a member of the project team, said the endoscope is the "most

advanced tool that exists right now for [single cell] studies."

The researchers' results were published in Nature

Nanotechnology, the top nanotechnology journal according to Gogotsi. The article

appeared on the journal's website in December and in print in January.

"Researchers in the … world are excited" about the

opportunities the cellular endoscope could create, Gogotsi said. He added that

in science many discoveries become possible due to new tools, and that "we

believe the [endoscope] will help us understand how cells function better than

we do now."

The research team has had a conference with what Gogotsi

said was a "major company" that is interested in licensing the endoscope

technology. Drexel has also filed five patent applications and two provisional

patent applications related to the project.

Gogotsi added that it could take a few years before the

cellular endoscope technology is available commercially. He said this is typical

in such situations.

The team has worked with Drexel's Office of Technology

Transfer and Commercialization, which works on protecting intellectual property

as well as marketing and licensing Drexel research.

Gogotsi said Drexel wants to "really affect [the] life

of people" through scientific and technological advances. He said he hopes the

endoscopes will eventually be produced in large quantities.

The Drexel researchers who created the endoscope come

from disciplines including electrical engineering, materials science and

engineering, biology and biochemistry and biomedical engineering.

"People with all this background were working together

as a team" to solve this issue, Gogotsi said. He credited the team's breadth of

knowledge for the creation of the endoscope.

Gogotsi said working with and learning from the members

of the interdisciplinary team was one of the most rewarding parts of the project

for him, adding that the ability to assemble a team with experts from different

fields is one example of the benefits of a research university.

The team members are a part of the A.J. Drexel

Nanotechnology Institute, which allows different disciplines to work together on

nanotechnology issues, according to Gogotsi.

He said in modern science, most discoveries are made by

teams, since most discoveries that can be made by individuals have already been

made.

Singhal said it was "a great learning experience

interacting with people from the different departments."

Singhal said the endoscope project has been his most

memorable experience at Drexel.

He added that the process was challenging and often did

not yield the desired results, but that when things worked correctly it was

"very delightful."

Singhal is currently helping with a project that is an

extension of the single-cell endoscope. The new project involves using carbon

nanotubes to remove and separate the contents of a cell. Singhal added that the

project could potentially have many industry applications for separating very

small particles, such as in crude oil.

As part of his work with the original project, Singhal

made a presentation in an engineers' conference in Vancouver, Canada. He said

other Drexel researchers have also presented on parts of the endoscope project.

Funding for the single-cell endoscope project was

provided by the W. M. Keck Foundation. The Foundation provided a grant of $1

million, according to Gogotsi, and also established the Keck Institute for

Attofluidic Nanotube-based Probes at Drexel, according to the Drexel team's

article in Nature Nanotechnology.

The Drexel team has used the Keck Foundation's funding

for the past three years, according to Gogotsi.

According to the Drexel press release on the project,

funding was also provided by a Nanoscale Interdisciplinary Research Team

National Science Foundation grant.

NANOTECHWIRE.COM 1/16/2011 5:38:48 PM

UNC researchers inch closer to unlocking potential of synthetic blood

A team of scientists has created particles that closely

mirror some of the key properties of red blood cells, potentially helping pave

the way for the development of synthetic blood.

The new discovery – outlined in a study appearing in the online Early Edition of

the Proceedings of the National Academy of Sciences during the week of Jan. 10,

2011 – also could lead to more effective treatments for life threatening medical

conditions such as cancer.

University of North Carolina at Chapel Hill researchers

used technology known as PRINT (Particle Replication in Non-wetting Templates)

to produce very soft hydrogel particles that mimic the size, shape and

flexibility of red blood cells, allowing the particles to circulate in the body

for extended periods of time.

Tests of the particles’ ability to perform functions

such as transporting oxygen or carrying therapeutic drugs have not been

conducted, and they do not remain in the cardiovascular system as long as real

red blood cells.

However, the researchers believe the findings –

especially regarding flexibility – are significant because red blood cells

naturally deform in order to pass through microscopic pores in organs and narrow

blood vessels. Over their 120-day lifespan, real cells gradually become stiffer

and eventually are filtered out of circulation when they can no longer deform

enough to pass through pores in the spleen. To date, attempts to create

effective red blood cell mimics have been limited because the particles tend to

be quickly filtered out of circulation due to their inflexibility.

Beyond moving closer to producing fully synthetic blood,

the findings could affect approaches to treating cancer. Cancer cells are softer

than healthy cells, enabling them to lodge in different places in the body,

leading to the disease’s spread. Particles loaded with cancer-fighting medicines

that can remain in circulation longer may open the door to more aggressive

treatment approaches.

“Creating particles for extended circulation in the

blood stream has been a significant challenge in the development of drug

delivery systems from the beginning,” said Joseph DeSimone, Ph.D., the study’s

co-lead investigator, Chancellor’s Eminent Professor of Chemistry in UNC’s

College of Arts and Sciences, a member of UNC’s Lineberger Comprehensive Cancer

Center and William R. Kenan Jr. Distinguished Professor of Chemical Engineering

at N.C. State University. “Although we will have to consider particle

deformability along with other parameters when we study the behavior of

particles in the human body, we believe this study represents a real game

changer for the future of nanomedicine.”

Chad Mirkin, Ph.D., George B. Rathmann Professor of

Chemistry at Northwestern University, said the ability to mimic the natural

processes of a body for medicinal purposes has been a long-standing but evasive

goal for researchers. “These findings are significant since the ability to

reproducibly synthesize micron-scale particles with tunable deformability that

can move through the body unrestricted as do red blood cells, opens the door to

a new frontier in treating disease,” said Mirkin, who also is a member of

President Obama’s Council of Advisors on Science and Technology and director of

Northwestern’s International Institute for Nanotechnology.

UNC researchers designed the hydrogel material for the

study to make particles of varying stiffness. Then, using PRINT technology — a

technique invented in DeSimone’s lab to produce nanoparticles with control over

size, shape and chemistry — they created molds, which were filled with the

hydrogel solution and processed to produce thousands of red blood cell-like

discs, each a mere 6 micrometers in diameter.

The team then tested the particles to determine their

ability to circulate in the body without being filtered out by various organs.

When tested in mice, the more flexible particles lasted 30 times longer than

stiffer ones: the least flexible particles disappeared from circulation with a

half-life of 2.88 hours, compared to 93.29 hours for the most flexible ones.

Stiffness also influenced where particles eventually ended up: more rigid

particles tended to lodge in the lungs, but the more flexible particles did not;

instead, they were removed by the spleen, the organ that typically removes old

real red blood cells.

Synthetic red blood cell mimics measuring 6

micrometers across, passing through a 3 micrometer diameter channel in a

microfludic device used to test the particles’ flexibility. The particles shown

had already squeezed through about 50 such channels without losing their shape

or elasticity. Video courtesy Timothy J. Merkel and Joseph M. DeSimone,

University of North Carolina at Chapel Hill.

The study, “Using Mechano-biological Mimicry of Red

Blood Cells to Extend Circulation Times of Hydrogel Microparticles,” was led by

Timothy Merkel, a graduate student in DeSimone’s lab, and DeSimone. The research

was made possible through a federal American Recovery and Reinvestment Act

stimulus grant provided by the National Heart, Lung and Blood Institute, part of

the National Institutes of Health (NIH). Support was also provided by the

National Science Foundation, the Carolina Center for Cancer Nanotechnology

Excellence, the NIH Pioneer Award Program and Liquidia Technologies, a privately

held nanotechnology company developing vaccines and therapeutics based on the

PRINT particle technology. DeSimone co-founded the company, which holds an

exclusive license to the PRINT technology from UNC.

Other UNC student, faculty and staff researchers who

contributed to the study are Kevin P. Herlihy and Farrell R. Kersey from the

chemistry department; Mary Napier and J. Christopher Luft from the Carolina

Center for Cancer Nanotechnology Excellence; Andrew Z. Wang from the Lineberger

Center; Adam R. Shields from the physics department; Huali Wu and William C.

Zamboni from the Institute for Pharmacogenomics and Individualized Therapy at

the Eshelman School of Pharmacy; and James E. Bear and Stephen W. Jones from the

cell and developmental biology department in the School of Medicine.

The study is an example of the type of research that

supports the Innovate@Carolina Roadmap, UNC’s plan to help Carolina become a

world leader in launching university-born ideas for the good of society. To

learn more about the roadmap, visit innovate.unc.edu.

Journal website: http://www.pnas.org

NANOTECHWIRE.COM 1/12/2011 4:24:17 PM

Argonne battery technology helps power Chevy Volt

This month, thousands of new Chevy Volt owners will begin

the real road tests of the first mass-produced plug-in hybrid electric car.

While much of the car's engineering is unique, consumers may be unaware that

some of its most extraordinary technology is inside the nearly 400-lb. battery

that powers the vehicle in electric mode.The

battery's chemistry is based in part on a revolutionary breakthrough pioneered

by scientists at the U.S. Department of Energy's Argonne National Laboratory.

The new development helps the Volt's battery—a lithium-ion design similar to

those in your cell phone or laptop—last longer, run more safely and perform

better than batteries currently on the market.

"To me this cuts right to the heart of green energy,"

said Jeff Chamberlain, who heads Argonne's battery research and development.

"This battery technology is a step towards energy independence for the U.S.; it

helps create jobs; and it can have a positive impact on the environment."

The story begins in the late 1990s, when the DOE's

Office of Basic Energy Sciences funded an intensive study of lithium-ion

batteries.

"Existing materials weren't good enough for a high-range

vehicle," explained Michael Thackeray, an Argonne Distinguished Fellow who is

one of the holders of the original patent. "The Argonne materials take a big

step forward in extending the range for an electric vehicle."

In order to improve the design, scientists had to know

how batteries worked at the atomic level.

"What we really needed to do was understand the

molecular structure of the material," said Argonne chemist Chris Johnson.

At its most basic level, a lithium battery is composed

of a negatively charged anode and a positively charged cathode. Between them is

a thin membrane that allows only tiny, positively charged lithium ions to pass

through. When a battery is fully charged, all of the lithium ions are contained

in the anode. When you unplug the battery from the charger and begin to use it,

the lithium ions flow from the anode through the membrane to react with the

cathode—creating an electrical current.

The team wanted to improve the cathode, the positively

charged material. They began by using incredibly intense X-rays from Argonne's

Advanced Photon Source synchrotron to monitor and understand reactions that

occur in lithium batteries—in real time. Next, they set out to modify and

optimize the cathode materials. Using new synthesis methods, they created

lithium- and manganese-rich materials that proved remarkably more stable than

existing designs.

Because manganese-rich cathodes are more stable than

those used in today's batteries, the new batteries are safer and less likely to

overheat. Manganese is cheap, so the battery will cost less to manufacture. The

researchers also upped the upper charging voltage limit to 4.6 volts—higher than

the usual operating voltage—and saw a tremendous jump in the battery's energy

capacity.

The Argonne battery design became, in a radical leap

forward, cheaper, safer, and longer-lasting.

"To me, that's exceptional," Chamberlain said. "New

advances often sacrifice cost or safety for performance; it's a rare

breakthrough that improves all three."

Batteries for electric and plug-in hybrid cars are much

larger—and thus far more expensive—than laptop batteries, and they make up a

large percentage of the car's price. Lowering the cost of the battery will lower

the cost of all-electric and hybrid cars, according to Khalil Amine, an Argonne

senior materials scientist, and subsequent improvements will improve battery

performance even further.

"Based on our data, the next generation of batteries

will last twice as long as current models," Amine said.

The team—especially the co-holders of the original

patent: Thackeray, Johnson, Amine, Jaekook Kim and Sun-Ho Kang—is happy to see

the technology make its way from the laboratory to the road.

"I would love to point to a car on the street and tell

my son, 'This car has our invention in it!'" Amine said.

"Seeing homegrown innovations going into a large-scale

production like the Volt—that's really exciting and good for America," Johnson

added. "It's really the ultimate goal for a researcher."

Furthermore, Chamberlain said that the new battery

technology pioneered by the lab can boost American manufacturing and create new

jobs.

"Batteries are a large, heavy component of electric and

hybrid cars, and so it's best to manufacture them near the factory where the

cars are assembled," Chamberlain explained. "This means cars assembled in U.S.

factories will also need battery factories nearby—creating more American jobs."

A total of $1.5 billion in stimulus grants went to

several companies last year—including A123 Systems, Johnson Controls and Compact

Power, an LG-Chem subsidiary—to build battery plants in the U.S. (A full list of

the grants is available online.)

Chamberlain, who worked in private industry for 13 years

before joining Argonne in 2006, says the national laboratories play a crucial

role in developing these kinds of breakthrough technologies. "The labs perform

basic research," he said. "In the U.S., businesses tend to invest in research

that will pay off in the short term; in this field of research, the national

laboratories are filling a gap by conducting the essential research that will

change the game ten to 20 years down the road."

When companies show interest in the technology, he said,

the labs collaborate with them to help adopt the method for large-scale

production.

LG Chem licensed the technology from Argonne and used

the materials to create the battery supplied for the 2011 Volt. GM has also

licensed the technology for their own tests.

"Seeing this play out is absolutely gratifying,"

Chamberlain said. "We're developing technology that I'm highly confident will

help make plug-in hybrid cars more economic. The work at Argonne ends up in the

hands of taxpayers who paid for research. This is a fulcrum, a key component to

moving away from fossil fuels."

The technology remains available for licensing.

Argonne National Laboratory seeks solutions to pressing

national problems in science and technology. The nation's first national

laboratory, Argonne conducts leading-edge basic and applied scientific research

in virtually every scientific discipline. Argonne researchers work closely with

researchers from hundreds of companies, universities, and federal, state and

municipal agencies to help them solve their specific problems, advance America

's scientific leadership and prepare the nation for a better future. With

employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC

for the U.S. Department of Energy's Office of Science.

|

© 2000 University of Massachusetts Lowell, Class Connections

|

Graphics & Design by: Thomas Pimental & Michelle Christman

In Association with: CLASS Connections |