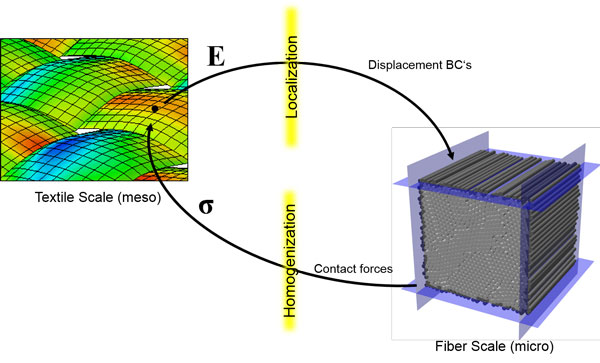

Multi-Scale Model

While computational models of structural composite parts have been a highly researched topic, detailed models of the manufacturing processes are still in their infancy. Research of the manufacturing process of textile reinforced composites, particularly at the preform stage before a matrix has been added to lock the fibers into place, is needed to predict fiber orientation and distribution in the finished part, along with local fiber defects such as gaps, loops, and folds. The difficulty inherent in considering the textile without matrix is it’s fragility and complexity. The textile is made from an intertwining of tows, and each tow is a bundle of thousands of individual fibers which are often only loosely bound to each other. Continuum models have shown extremely limited success in representing a textile, and experimental characterization methods used for typical structural materials have almost no applicability. Furthermore, fiber-scale factors, such as the polymeric sizing used to bind fibers together and reduce friction, have a huge impact on the manufacturability of the tows. Only trial and error is presently used to determine the broad effects of these micro-scale parameters.

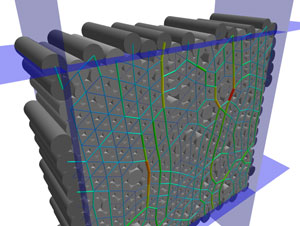

One of my present research topics is to create computational models for textile preforms which will be used to predict the final part microstructure based on the manufacturing process. Fiber-scale and multi-scale models are being considered in order to capture the desired physics with the greatest computational efficiency. Furthermore, experimental test methods will be developed to characterize textiles at the fiber, tow, and textile scale.